|

|

"Woodgas" is my name for the various gases that can be easily made from

wood or biomass. Various forms are: synthesis gas,

typically 40% hydrogen, H2, 40% carbon monoxide, CO, 3% methane, and 17%

Carbon dioxide; producer gas, made by gasifying biomass with air

(and therefore containing ~50% nitrogen); pyrolysis gas, similar

to synthesis gas, but including lots or water and tar and

accompanied by production of 10-30% charcoal.

The Industrial Revolution was

fueled by gas starting in 1800 (primarily from coal

by pyrolysis) initially used for city and home lighting,

then for cooking and power generation. Coke

for steel making was a useful by-product. By 1850, the major

cities of the world had "gaslight" (see Dickens

novels). The internal combustion engine was

invented to make electricity from producer

gas about 1880. See all the wonderful

old coal systems in our book "Modern Gas Producers" on

our Books

page. All of this changed starting in 1930, when welded

pipelines brought natural gas from oil wells to

our houses and now few of us remember the producer gas

(manufactured gas, city

gas, water gas etc.) era.

During World War II over a

million gasifiers were built for the civilian sector while the

military used up all the gasoline. Now that world oil supplies

are being depleted and global warming is perceived as a threat

to our environment, there is renewed interest in gas from

BIOMASS. The National Academy of Sciences published a

great booklet on "Producer Gas: Another Fuel for Motor

Transport" in 1983, and we are into our third printing at

the BEF PRESS (see BEF Books).

We show here a few interesting old pictures from that book. (Click

each thumbnail to view large and return here with Back button)

and a few more

modern ones from the late 1970s-early 80s.

Old & Modern

Gasifiers

On March 9, 2001 I

visited a Mr. Mel Strand at his home in Boulder, CO. Mel

was born in Minneapolis, but during WWII he was stranded in

Norway during the occupation and drove a gasifier truck -

delivering groceries in the day and weapons to the underground

at night.

Mel returned

to the U.S. after the war and his career has been in machining

and fabrication. As a hobby a few years ago he decided to

construct the gasifier he remembered it from a 1948 Chevy

pickup. What a beauty he made!

Mel turned on the

auxiliary starting fan, and started the gasifier on large aspen

chunks with a newspaper. After a few minutes he lit the

gas at the front of the truck and started the engine. We

drove around Colorado Springs for several hours. I

realized what an art it was to drive a gasifier car, since he

could control the spark advance, air fuel ratio and throttle,

all from the steering column, while talking about the old and

new days.

Modern Small

Gasifiers

| A great deal of

development of gasifiers is going on around the world.

In

1999 I collaborated with the

company Community Power, CPC,

Corporation, CPC, to build a 5 kW

"Turnkey, Tarfree" gasifier using new principles I had

discovered and learned. The picture at the right shows

Kurt Kirscher, Shivayam Ellis, myself, Agua Das and Robb Walt

(President of CPC) outside my laboratory.

|

|

CPC

developed this gasifier with the aid of grants from the US DOE,

Shell International, the California Energy commision ant others

into field gasifiers tested in Alaminos in the Philippines and

the Hoopa Valley Indian Reservation in California.

CPC

is now quite active in many aspects of gasifier research and has

a dozen 15 kW "Turnkey, Tarfree" gasifiers in the

field and used by the US Forest Service and Others to turn

forest litter and biomass trash into heat and power. CPC is now

also developing a 5 kW heat/power and a 50 kW gasifier.

|

|

|

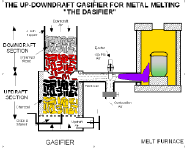

THE DASIFIER

FOUNDRY GASIFIER

Here's a nifty

gasifier developed by my colleague and

co-author, Agua Das, for melting bronze and other metals

with biomass. Built from tincans and a

refrigerator compressor, it burns all kinds of biomass trash.

I also call it an "up-down draft gasifier. See

the description at "Dasifier".

|

|

BIG GASIFIERS

I have lots of

descriptions of large gasifier projects in my book "Survey

of Biomass Gasification - 2000" (see Books).

Here is the famous Burlington Vt. 5 MW fluidized bed that makes

a very rich gas of 15 MJ/m3. It is based

on the double fluidized bed developed at Battelle and has been

scaled up by FERCO and the US Dept. of Energy. It operates

on wood chips from the Vermont forests. I

believe it is no longer in operation (July, 2004).

The BEF is involved

with research, design and construction of all gasifier sizes.

|

|

GASIFIERS FOR

FUELS AND CHEMICALS

When biomass is

gasified with air the resulting gas has ~50% nitrogen,

and so is good only for use at the point of origin. For

pipelines, for some storage or for chemical synthesis,

oxygen gasification produces a gas

with twice the energy (~12 MJ/m3) while pyrolytic

gasification can produce a gas with 20 MJ/m2.

In 1973 at

MIT, I wrote the lead article for the journal Science,

"Methanol:

A versatile Fuel for Immediate Use", (Vol. 182, pp 1299,

1973). Unfortunately,

the US chose not to develop fuels alternative to gasoline and so

has been exporting money for oil to finance terrorists.

Read the sad story at our Methanol

page.

In 1980 we built an

oxygen gasifier at SERI/NREL which eventually was tested on pure

oxygen at the 25 ton/d level. This is discussed in our

book FUNDAMENTAL STUDY AND SCALE UP OF THE AIR-OXYGEN STRATIFIED

DOWNDRAFT GASIFIER on the Books

Page.

|